-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Summary of Experimental Analysis of Laser Welding Process for Power Battery Tabs

Summary of Experimental Analysis of Laser Welding Process for Power Battery Tabs

Category: battery industry Author: battery laser welding 2017-12-25

The purpose of the experiment: stack 4 pieces of 0.2mm pole lugs (aluminum or copper nickel-plated pole lugs) together and weld them on the aluminum or copper pole to achieve a smooth welding seam.

Experiment 1:

Laser

YLS-4000 (100um fiber)

Mode CW continuous

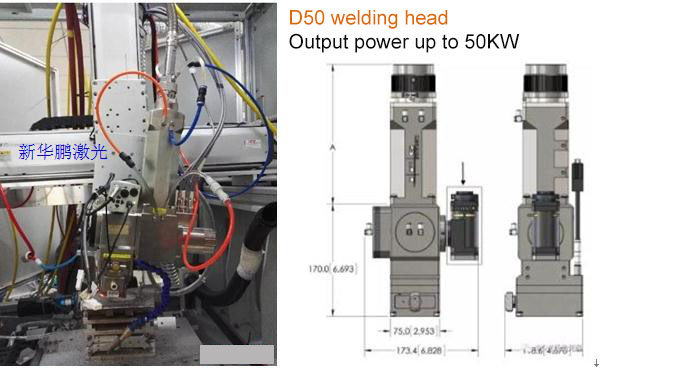

Laser head (nozzle) D50 (output power up to 50kW)

Focal length: FC = 200, FF = 250mm

CNC platform or robotic hand; four-axis motion platform

Battery tab laser welding head

Experimental materials used:

Material grade; aluminum sheet, copper nickel plated sheet, aluminum pole shape (plate, block, wire)

Sheet

Size: 0.2mm pole, 1mm pole

Laser welding of battery tabs

Experimental results:

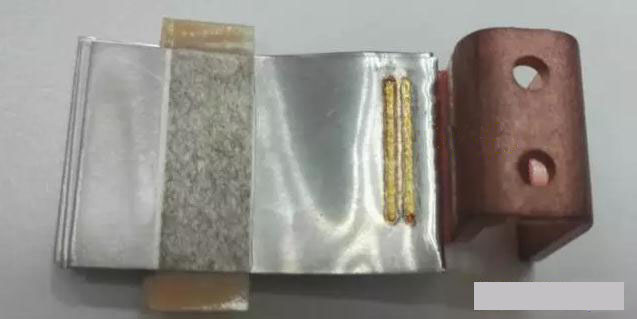

4 pieces of nickel-plated copper lugs welded to the copper pole

Power: 2400 watts

Thickness: 1mm, 4 layers

Speed: 100mm/s Laser welding of battery copper pole

4 pieces of aluminum pole lugs are welded to the aluminum pole

Power: 1600 watts

Thickness: 1mm, 4 layers

Speed: 100mm/sec

Aluminum pole laser welding

Summary:

After using the fixture, the welding effect is relatively good.

This welding is one weld and one weld separately.

Through the test, it can be found that the biggest factor that affects the welding effect is whether the tabs are compressed.

The welding effect after compaction is obviously better than the effect without compaction.

At the same time, it also explains that when laser welding any material, it is necessary to ensure that the distance between the materials needs to be within the appropriate range. Too large or small will affect the welding effect, especially for the processing of deep penetration welding, too small gap will cause welding The gas cannot be discharged in time, resulting in pores, and if it is too large, penetration will affect the quality of the process.

Tel:+86 0755-89302056

+86 0755-85200585

Web: https://www.shinhop.com/(CHN)

https://www.shinhop.com/en/ (EN)

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China